Controlled Robotics for Efficient Circuit Diagram AI-powered systems enable automated inventory tracking and optimization, allowing warehouses to monitor stock levels, locations, and movements in real-time (Lebhar .2022). Advanced computer vision

Moreover, AI enhances operational workflows through automated picking and packing systems, which streamline order fulfillment processes, reduce human error, and improve throughput. Moreover, robots powered by AI work alongside human staff to move goods more efficiently within the warehouse, tackling heavy lifting and repetitive tasks. The code creates an AI-powered warehouse management system with document processing and interactive chat capabilities. While building this application, my focus was on creating an intuitive user interface that effectively handles Excel documents, processes them for analysis, and enables natural conversation with the data. Image showing why AI Software Development for WMS matters. Improved Operational Efficiency: AI-based WMS can automate inventory tracking, order picking, and shipping, leading to faster processing times and fewer errors. Optimized Inventory Management: AI algorithms can look at historical data and trends to optimize inventory, reducing both overstocking and stockouts.

How Dynamics 365 ERP Empowers Warehouse Management with AI and Automation? Circuit Diagram

4 Ways to Automate Your Warehouse . Having worked on various WMS projects, we can confidently outline four key areas where you can implement automation to transform your warehouse into a lean order-fulfilling machine.. Automated inventory management. A warehouse management system is the software backbone of a modern warehouse, connecting various aspects of logistics operations into a single

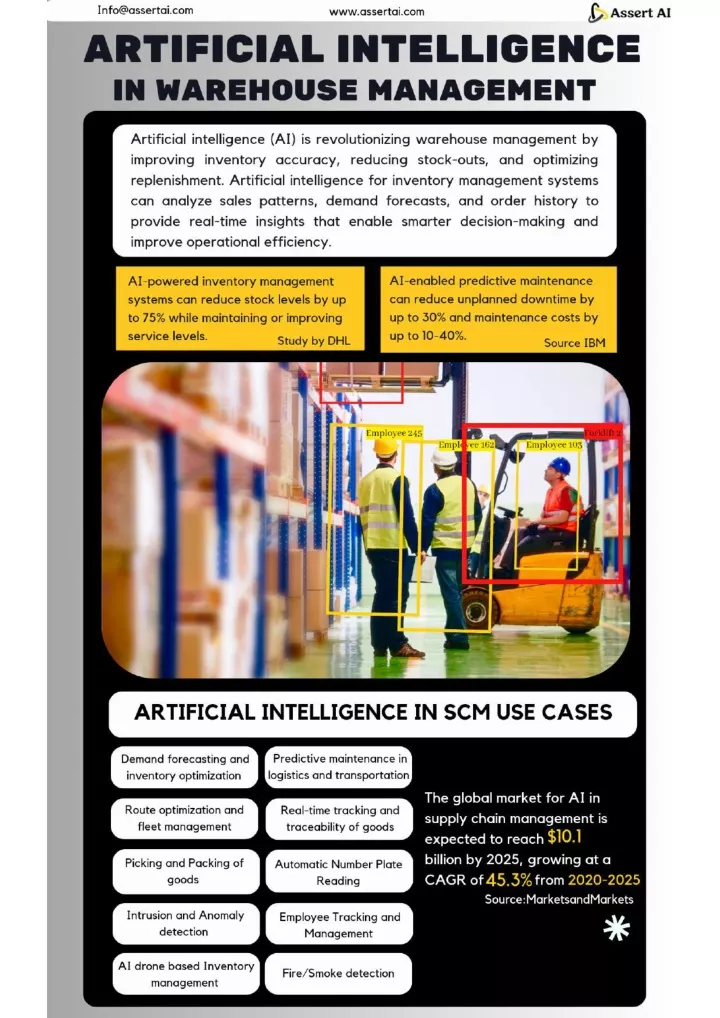

The integration of AI and automation in warehouse management through Microsoft Dynamics 365 ERP is revolutionizing the way businesses handle their supply chains. With intelligent inventory management, AI-powered order fulfillment, and automated workflows, companies can enhance efficiency, reduce costs, and improve overall operational effectiveness. We came across some encouraging statistics and numbers that suggest that the global warehouse management system market value is expected to touch approximately $13.34 billion by 2030 at a CAGR of 19.5%. Similarly, Global Trade Magazine has anticipated that AI in Warehouse Management will grow at a CAGR of 39% during the period 2024-2033.

driven warehouse automation: A comprehensive review of systems Circuit Diagram

Intelligent route planning: An AI-powered warehouse management system determines the most efficient picking route, minimising travel time in the warehouse and speeding up order fulfilment. Voice-controlled picking: An AI-powered voice recognition system guides employees through the picking process, improving accuracy and reducing the time it